ForgeX Polska offer the following NDT: magnetic particle inspection and hardness testing.

The MP Inspection aims at detecton of surfacne cracks and defects. It is a part of defectoscopy tests. ForgeX Polska have two devices for these tests:

CGM - for aerospace forgings.

and

Carl Deutsch – for automotive forgings.

CGM Defectoscope.

This device has a reliable structure made of painted sections and is provided with a MINICEM 1000/30 control unit that includes:

- 2 magnetising headers

- 1 power coil

- mobile set of buttons

- 1 steering rod

- 1 steering pedal

- Spraying system

- Container for dripping liquid

- Magnetic liquid recirculation system, hydraulic

- Pneumatic system

- Power switch

Karl Deutsch Defectoscope.

The device is composed of three basic components: testing unit, control cabinet, detection liquid container with a pump. In the UWE device these three components are integrated into one compact machine.

The defectoscope is provided with the following components:

- continuous setting for current and field flow,

- control of the upper and lower limits for current flow,

- device for switching testing cycles on with automatic application of liquid

- additional hose for sprinkling the liquid

- demagnetizing unit

- crawl switching for current and field flow

- UV lamp

Hardness Testing.

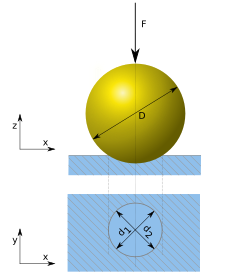

ForgeX Polska offer hardness testing based on the Brinell method. It is the quickest non-destructive method to measure the forgings. It is used for quick statistical check of a manufacturing lot. A steel ball of 10mm-diameter is used to check non-machined surfaces. The ForgeX Polska standard is to verify a 10% sample of the lot. In case of additional requirements communicated by the customer, it is possible to check a sample of any size. It is also possible to verify it using laboratory method but this results in a destruction of the forging.

Metrology Tests.

Currently ForgeX Polska are able to check the dimensions of the products using a CMM machine. It ensures full control of the product and reduces the risk of non-conformances significantly. Our Mitutoyo machine is a particularly necessary device to check as-machined products in ForgeX Polska.